Effective inventory management is essential for the smooth operation of any industry or business. Advanced inventory management software development guide provides valuable insights. Explore its features, different types, trends, use cases, and costs to help you make well-informed decisions.

Dealing with inventory can pose significant challenges for businesses. However, by utilizing effective inventory management software, you can streamline the process and avoid the common issue of running out of stock.

The Strategic Guide to Inventory Management Software Development

A well-designed inventory management system is essential for maintaining optimal stock levels, as shortages can have a negative impact on your revenue and overall profitability, potentially jeopardizing your business.

Moreover, as technology continues to advance and streamline business processes, sticking to manual data entry is inadvisable. In the meantime, take some time to educate yourself on this topic by reading the following article.

Read: Farm Management Software Development

What is Inventory Management Software?

Inventory management software is a crucial tool utilized by businesses to effectively oversee and control their inventory or stock in real time. This comprehensive system serves as an essential component in assisting organizations in monitoring their products, raw materials, and the associated tasks related to inventory management.

The software acts as a valuable assistant by simplifying and automating various inventory management processes, thereby minimizing errors and enhancing overall productivity.

Moreover, the software's capacity to provide real-time visibility of inventory enables companies to promptly address fluctuations in demand and supply, ensuring they maintain optimal product availability levels at all times.

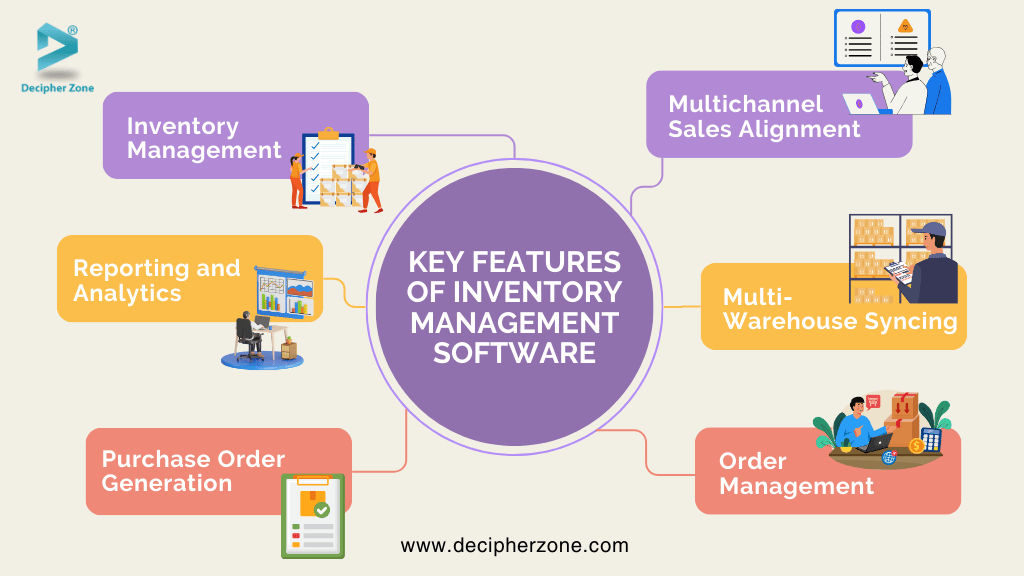

Key Features of Inventory Management Software

When it comes to inventory management software, there is a wide array of features that can be integrated to enhance operational efficiency. It's important to select the ones that best suit your business needs and contribute to overall efficiency.

1. Inventory Management

One of the major features of inventory management software is its capability to optimize storage space by providing data-driven insights on inventory movement, stock levels, and demand patterns.

Additionally, it effectively allocates financial resources by allowing for strategic investment in high-demand products and minimizing excess stock of slow-moving items.

2. Reporting and Analytics

Utilizing advanced reporting and analytics tools enables you to pinpoint which goods or products have the highest and lowest turnovers. These valuable insights are crucial for influencing future stock re-orders.

This feature also offers real-time, in-depth visibility into critical supply chain management components, allowing you to preempt stockouts, implement automatic reorders, and receive automatic stock updates as sales are made.

3. Purchase Order Generation

Inventory management software streamlines the procurement process by automatically creating and transmitting purchase orders to designed vendors. The purchase orders are comprehensive, containing detailed information about the required items, quantity, and any specific instructions, ensuring efficient and accurate procurement.

4. Multichannel Sales Alignment

An inventory management system software plays an important role in streamlining and organizing inventory data entries, ensuring seamless synchronization across multiple sales channels.

This significantly alleviates the workload associated with estimating stock locations, as the software provides accurate and real-time visibility into the status and whereabouts of various in-stock products.

Read: School Management Software Development

5. Multi-Warehouse Syncing

This feature allows managers with the capability to seamlessly synchronize and update inventory data across different retailers and warehouses. As a result, it ensures that stock levels are accurately and consistently maintained, optimizing inventory management and minimizing the risk of stockouts or overstocking at each location.

6. Order Management

Effective inventory management system software ensures that the stock is sufficient to fulfill customer orders. One of its key features is alerting managers or staff when stock levels are low. It can automate product orders from wholesalers before the inventory runs out and becomes understocked.

Types of Inventory Management Software

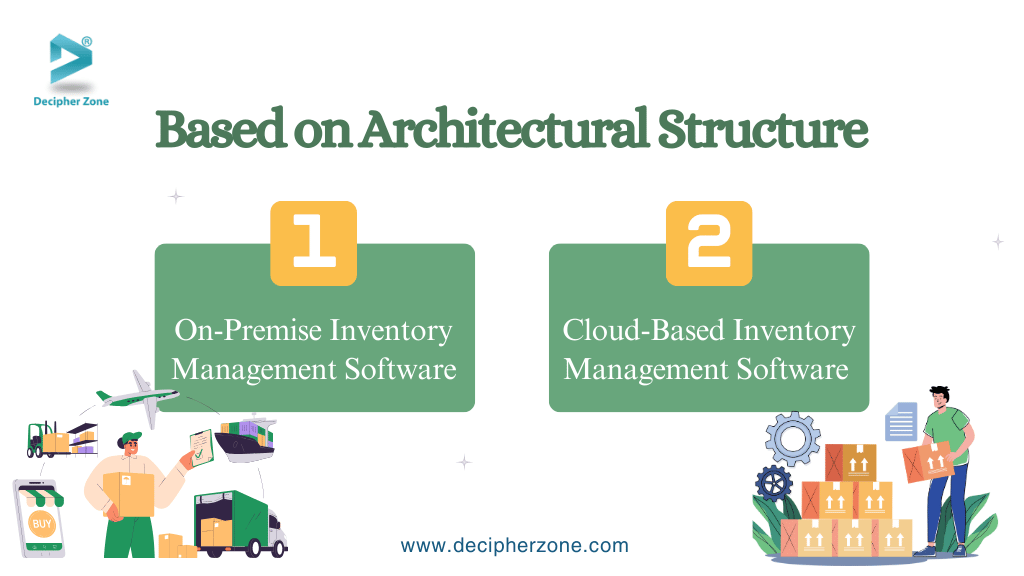

Customize your inventory management software solution to the highest degree. This can encompass a variety of factors, with a primary focus on architectural structure and technologies. The following detailed description will provide a clear understanding of how inventory management software systems can best meet your organization's needs.

A- Based on Architectural Structure

- On-Premise Inventory Management Software

This model involves installing the inventory management software on the company's own servers at the local business premises.

On-premise inventory management software follows a traditional approach, operating within the company's physical infrastructure, where the team is responsible for managing and maintaining the software. This necessitates optimal resources such as the IT team to oversee updates, security, and customization.

- Cloud-Based Inventory Management Software

This model entails hosting on remote servers and accessing through the internet, offering a modern solution. By adopting this approach, businesses are relieved of the responsibility of managing their own servers, which in turn leads to cost reduction by eliminating the need for extensive in-house IT resources.

Additionally, it allows software providers to take charge of system updates and maintenance, ensuring seamless operation and reducing the burden on the business.

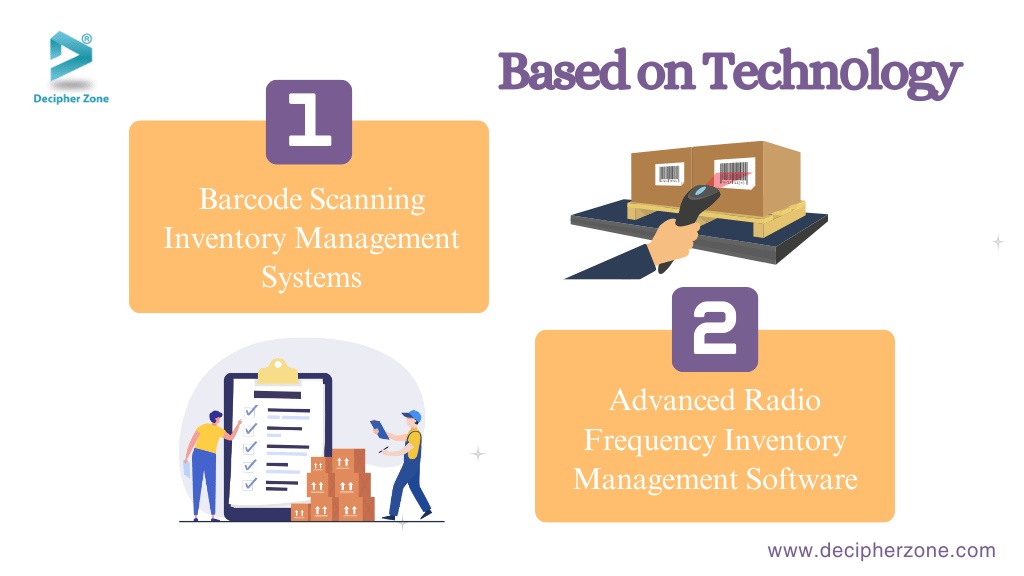

B- Based on Techn0logy

- Barcode Scanning Inventory Management Systems

This model offers increased flexibility for managing a wide range of products by scanning the barcode. It smoothly retrieves information directly from the Point of Sale, streamlining operations and simplifying the entire process.

- Advanced Radio Frequency Inventory Management Software

The cutting-edge radio frequency model leverages advanced technology to enhance the warehouse's material handling capacities greatly. By utilizing a combination of active and passive technologies, store managers can seamlessly monitor and track the inventory of thousands of products in real time.

This efficient system enables precise and comprehensive inventory management, empowering businesses to optimize their warehouse operations.

Read: Legal Case Management Software

Stages of Inventory Management System

Managing inventory involves several stages, making it easy and accurate to track goods from manufacturing through storage to sales. This process unfolds in five stages:

Purchasing or Reordering: Procurement is the process of obtaining raw materials required for the manufacturing of products or acquiring finished goods that are intended to be sold. This can involve sourcing, purchasing, and managing the materials or products necessary for a business's operations and sales.

Production: The process of production involves converting raw materials into finished goods through a series of steps such as processing, assembly, and quality control to prepare them for sale in the market.

Storage: Storage refers to the process of holding stocks of raw materials before they are used in production or finished goods before they are sold to customers. This is an essential part of supply chain management and inventory control, ensuring that the right amount of inventory is available at the right time to meet demand without excessive holding costs.

Sales: Delivering goods is an essential part of the sales process, ensuring that customers receive the products or services they have purchased.

Reporting: Reporting helps in monitoring and analyzing sales performance and profit margins to evaluate the financial health and success of a business.

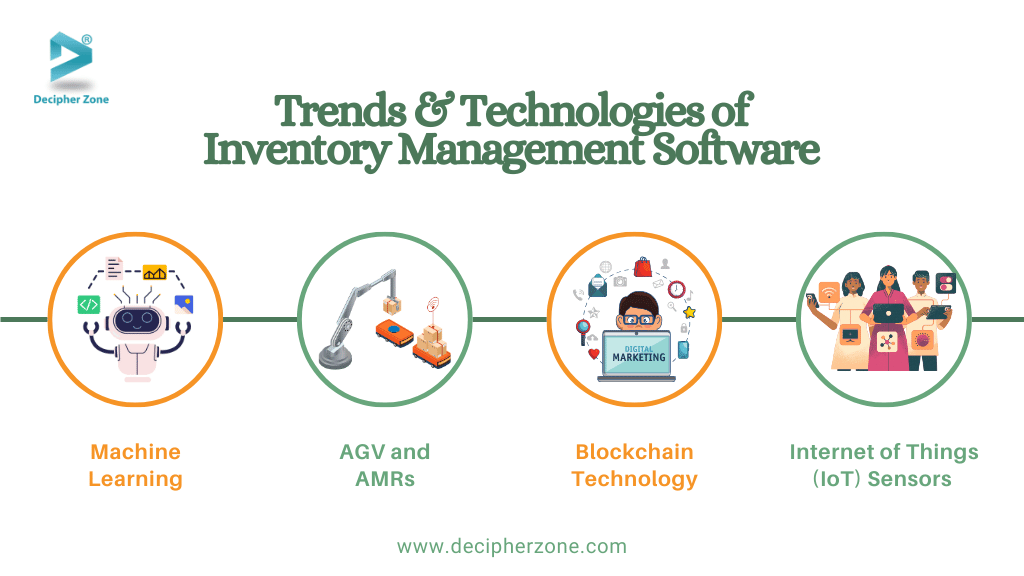

Trends & Technologies of Inventory Management Software

As businesses continue to leverage inventory management system software to streamline logistics and uphold precise records of product movement, ongoing technological advancements are further revolutionizing these processes. Following are the technologies discussed that help redefine the capabilities of inventory management software:

1. Machine Learning

Humans often engage in repetitive and time-consuming tasks, which can lead to errors in inventory management. Integrating an automated inventory tracking system with machine learning can significantly improve this process. It allows clients to easily search for items using voice or image recognition and predict future stock needs. Moreover, machine learning-driven inventory management features can promptly alert vendors of any disruptions in the supply chain.

2. Automated Guided Vehicles (AGV) and Automated Mobile Robots (AMRs)

Automated Guided Vehicles (AGVs) and Automated Mobile Robots (AMRs) are valuable tools for improving lead time and productivity. These robots are used in warehouse operations to pick or collect products from designated pallets and decks.

AGVs rely on magnetic strips to follow a predetermined path within the warehouse, making them unsuitable for facilities with frequently changing floor plans or numerous obstructions.

Read: What is CRM Software Development

On the other hand, AMRs represent a more advanced technology as they can navigate throughout the warehouse without being limited to fixed routes, thanks to their smart sensors. Both types of robots significantly reduce the time required to move products within the warehouse. If your business deals with heavy-weight products, investing in this technology could be beneficial.

3. Blockchain Technology

Blockchain technology provides transparency on a decentralized platform, ensuring that information remains confidential and unbiased and cannot be modified by any vendor or stakeholder. This enhances the reliability of the automated inventory tracking system, as all uploaded information must be exact and accurate for all stakeholders.

Moreover, blockchain solutions integrated with inventory management systems enable retail partners, suppliers, production places, manufacturers, and warehouses to collaborate and share real-time details.

4. Internet of Things (IoT) Sensors

Businesses can leverage the Internet of Things to facilitate communication between various devices. Virtually everything within a business environment, such as scanners, loading docks, machinery, and even the products themselves, can be connected to the local network. Increasingly, businesses are utilizing IoT sensors for inventory management and order processing.

Aside from ensuring product quality, these sensors boost efficiency by pinpointing operational bottlenecks and optimizing the flow within warehouses. The sensors mainly scan real-time inventory RFID tags and monitor product movement throughout the warehouse, allowing businesses to establish automated re-ordering triggers to prevent stock shortages.

Inventory Management Software Development Cost

Businesses that utilize inventory management system software to streamline their inventory management process often experience significant sales and profit growth. Nevertheless, the primary challenge lies in the overall implementation cost.

Whether it's an automated inventory tracking system, inventory management system, perpetual inventory system, or any other type of software, there's no fixed price tag. The cost of inventory management software is influenced by several factors. Once you understand these elements, the software development team can provide you with a pricing estimate.

Bottom Line

The world of inventory management software is evolving significantly in the coming years. Businesses that adopt these emerging trends can achieve a competitive advantage by streamlining their supply chain, improving customer satisfaction, and reducing operational inefficiencies.

From leveraging AI-generated insights to embracing sustainable practices and cutting-edge technologies, staying updated on these trends will be vital for success in the dynamic realm of inventory management.

Read: Apprenticeship Management Software

As we navigate the intricacies of today's business environment, these trends provide a roadmap to more effective, adaptable, and customer-focused inventory management strategies. We at Decipher Zone are honored to offer our expertise in developing customized inventory management software tailored to your precise needs.

FAQs

-

What is the inventory management software?

Inventory management software is a critical tool utilized by businesses to effectively oversee and control their inventory or stock in real-time. This comprehensive system serves as a crucial component in assisting organizations in monitoring their products, raw materials, and the associated tasks related to inventory management.

-

What are the 4 types of inventory management systems?

In inventory management, there are four main types: Just-in-Time Management (JIT), Materials Requirement Planning (MRP), Economic Order Quantity (EOQ), and Day Sales of Inventory (DSI).

-

How much time does inventory management software need to develop?

The duration for developing inventory management software can significantly differ based on elements like the complexity of the system, the team's size, and the technology utilized. Nevertheless, it commonly requires 6 to 8 months to 10 to 12 months to build and integrate a system of this kind.